Sustainable Building Solutions Are Driving the Construction Industry

Sustainability isn’t a buzzword anymore.

It’s becoming the defining priority of the modern building industry. From material selection to energy use to end-of-life planning, today’s building professionals are searching for sustainable building solutions that deliver real performance while reducing environmental impact. And insulation, long treated as a commodity, has emerged as one of the most powerful levers for change.

What It Means to Build for the Future

Changes in the construction industry are typically driven by four different priorities to make more planet-friendly choices:

- Decarbonization

- Electrification

- Materials

- Waste Reduction

Collectively, these four priorities represent a commitment to lower emissions, healthier environments, and a circular economy that values renewable, low-impact materials. And as building professionals seek new pathways to achieve these goals, insulation – an often overlooked yet impactful building material – is receiving renewed attention.

Insulation is a critical component of the built environment, reducing the dependency on active heating and cooling systems and providing stable temperature control during winter and summer months. Advances in insulation technology have led to sound dampening qualities, moisture management, and improved fire resistance.

Sustainable insulation products like wood fiber are gaining popularity as builders and homeowners are increasingly aware of the indoor air quality and health considerations associated with conventional insulation materials like fiberglass, mineral wool, and spray foam.

But insulation is just one area where the construction industry is pivoting toward more responsible materials and practices. Buildings are no longer just places to live and work – they’re part of a climate solution.

In this article, we’ll explain the priorities of the building industry driven by a desire to minimize climate impact and maximize building performance.

Buildings are no longer just places to live and work – they’re part of a climate solution.

Priority 1: Decarbonization

Reducing carbon footprints has long been a strategy toward greater sustainability. In the construction industry, better design and material selections can help reduce:

- carbon emissions associated with manufacturing materials

- heating, cooling, and powering a building

- material disposal

Embodied carbon has become an important way the industry can meet sustainability goals.

Unlike operational carbon, which are the emissions released during a building’s use, embodied carbon refers to the greenhouse gas emissions produced throughout the life cycle of a building: material extraction, manufacturing, transportation, installation, and end-of-life disposal.

According to a 2024 article by the World Bank, the construction, operation, and production of materials used in the building industry account for 40% of carbon emissions globally.

However, a 2023 International Finance Corporation report found global buildings and construction-related carbon emissions could drop 23% by 2035 through the implementation of energy-efficiency and electrification.

As we rethink building materials and design to help reduce embodied carbon, up-cycled, recyclable, bio-based, and low-carbon alternatives are gaining momentum. Some building materials that help reduce carbon emissions include:

- Bio-based materials like bamboo, hempcrete, straw, and cork.

- Recycled and upcycled materials like recycled steel, recycled plastics and glass, and recycled bricks.

- Low-carbon concrete alternatives like green concrete, ferrock, and ashcrete.

How Wood Fiber Helps Meet Carbon Goals:

Unlike conventional insulation materials like spray foam, which is made from petrochemicals and has a high level of embodied carbon, and fiberglass, which requires energy-intensive manufacturing and has moderate embodied carbon, wood fiber insulation is carbon-negative at the factory gate, storing more carbon than is produced during the manufacturing process: A1 (raw material supply) through A3 (manufacturing).

Wood fiber insulation stores biogenic carbon absorbed by trees, locking the carbon in buildings for the life of the material.

Read More: A Clear Difference: Wood Fiber Vs. Other Insulation Options

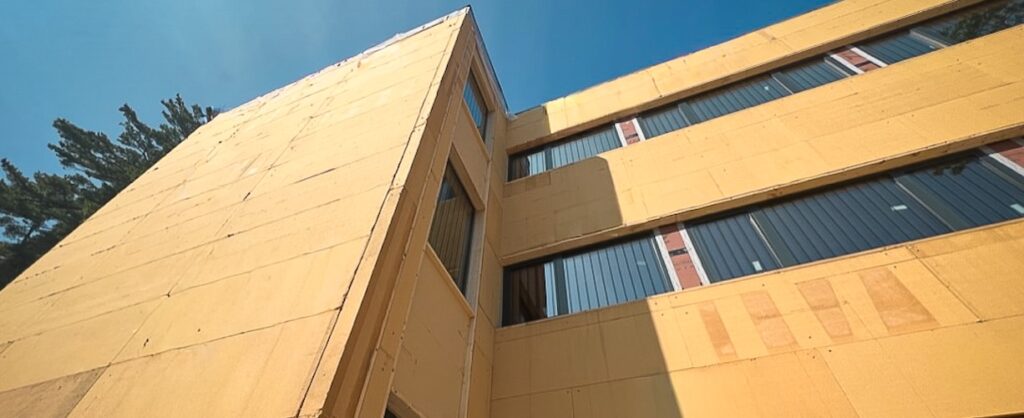

At TimberHP, we source clean, dry softwood residuals from regional lumber production – material that would otherwise be downcycled or burned. Wood fiber is naturally carbon-negative, storing more carbon than is released during manufacturing.

Buildings using wood fiber insulation lock away atmospheric carbon in the built environment, a significant step toward decarbonization.

Priority 2: Electrification and Building Envelope

The movement away from fossil fuels and toward electric power, or electrification, is reshaping how the construction industry approaches building performance. Some electrification solutions include:

- Electrified equipment, such as heat pumps, electric water heaters, electric cooking appliances, and energy-efficient lighting.

- Energy-efficient integrations like smart thermostats, solar panels, sealing ductwork, and closing air leaks and gaps around windows and doors.

Electrification can help make buildings more sustainable – but there is a catch. Without a high-performance building envelope, the benefits from those electric power solutions, especially efficiency integrations like smart thermostats and solar panels, can be less impactful.

Tight, well-insulated structures minimize energy loss and help stabilize indoor comfort, ultimately raising the efficiency of electric power systems.

How Wood Fiber Improves the Building Envelope:

Wood fiber insulation offers exceptional thermal performance and moisture management, contributing to a tight building envelope and enabling electric systems to operate at peak efficiency.

When coupled with renewable energy sources like solar or wind, buildings with robust envelopes can support net-zero strategies.

In other words, insulation is infrastructure for electrification. Choosing renewable materials ensures that this foundation aligns with broader sustainability goals, not against them.

Priority 3: Responsible Materials

Beyond carbon emissions and efficiency upgrades are the materials. Using materials that are carbon- or energy-intensive to produce, and that are not renewable or recyclable, undermines the sustainability impact.

Furthermore, some sustainable materials are coated or mixed with chemicals like flame retardants and petrochemical binders that are dangerous to handle during installation, and can release volatile organic compounds (VOCs) into indoor spaces once installed.

Specifiers and installers are increasingly selecting more responsible materials that don’t compromise on a major component of sustainability.

Some examples of more responsible alternatives to traditional materials include:

- Recycled steel, which is produced using melted and reformed scrap metal. This steel is considered sustainable when a significant amount is made from recycled content using EAF (Electric Arc Furnace) technology.

- Cool roofing, which uses reflective materials to minimize heat absorption and reduce the load on air conditioning systems.

- Green roofing, or a “living roof” system, which helps insulate roofs and manage rainwater, reducing energy usage and the urban “heat island” effect.

- Low-E windows, which have a special coating that reflects infrared light, keeping heat inside during winter and outside during summer.

- Cross-laminated timber, a wood-based strong and sustainable alternative to traditional concrete and steel for more energy-efficient construction.

- Phase-change materials, which reduce loads on HVAC systems by absorbing and releasing heat to regulate building temperatures.

How Wood Fiber Delivers Sustainability and Performance

Wood fiber insulation offers a high-performance thermal barrier; high R-values and thermal storage deliver year-round comfort, draft reduction, and stabilized temperatures, contributing to overall energy efficiency.

Plus, wood fiber insulation is renewable, reusable, and made from residuals. Its durability and density provide industry-leading sound dampening across walls, and wood fiber is vapor open for superior moisture management that promotes indoor air quality.

Waste Reduction

According to the World Green Building Council, the building industry produces one-third of the world’s waste, much of which ends up in landfills or incinerators. The WGBC posits that recycling alone won’t help companies reach net-zero or other carbon reduction goals – the solution is moving material consumption to a circular economy.

A circular economy in the building sector would mean designing out waste and pollution, keeping products in use for as long as possible and regenerating natural systems.

There are several examples of a circular economy currently in use in the building industry:

- Deconstruction: Recovering building materials at end-of-life that can be reused or recycled.

- Cradle to Cradle (C2C): Using materials with infinite lifecycles – meaning they can be continuously reused without losing value or performance.

- Modular and Customizable Units: Building components designed to be assembled, broken down, and relocated for continuous use in different configurations.

- Digitalization: Building Information Modeling (BIM) tools can increase operational efficiency, reduce waste, and improve visibility into material availability and reuse potential.

- PaaS Business Model: A product-as-a-service business model focuses on designing products for longevity, ease of maintenance, reconditioning, and ability to be continuously reused.

How Wood Fiber Reduces Building Material Waste

Wood fiber insulation is a highly responsible building material. In addition to being circularity-aligned, it is made using residual byproducts from normal forestry activities that would otherwise be discarded.

This circular approach transforms natural softwood chip waste into a valuable, high-performance insulation solution, closing the loop on material life cycles and reducing the building industry’s dependence on virgin, nonrenewable resources.

While the U.S. does not yet have a large-scale circular pathway for wood fiber insulation, the material is inherently compatible with future circular systems due to its clean fiber composition.

In an era where builders are looking for solutions that align with LEED and Passive House certifications, and are compatible with IRC and IECC standards, renewable wood fiber insulation is a great choice for lower-impact, circular construction.

The Future of Insulation is Renewable

Wood fiber insulation has been used and trusted in Europe for more than 20 years. While it can be shipped to the U.S. for use in construction, the timelines and cost often present challenges for building projects.

For the first time, high-performance wood fiber insulation is manufactured in the United States at scale. TimberHP’s model supports regional manufacturing, rural job creation, and a renewable domestic supply chain—helping reduce reliance on petrochemical insulation products.

In the U.S., this shift is only beginning, but it’s accelerating fast.

U.S.-made wood fiber insulation supports an ecosystem of sustainable forestry and lumber production, rural economic revitalization, and low-carbon construction. This model demonstrates what a truly renewable supply chain can look like in America: local, regenerative, and built to scale.

To achieve a renewable future for the building industry, it will require the integration of many solutions, including carbon-negative and responsible materials, electrification, and circular thinking. Collectively, these trends point toward a new kind of building industry: one that doesn’t just minimize harm, but actively contributes to environmental restoration.

Policy frameworks — from state-level Building Performance Standards (BPS) to evolving energy codes like IECC 2021/2024 — are accelerating demand for low-carbon, high-performance materials that support healthier indoor environments. Even as certain IRA efficiency incentives approach their scheduled sunset, the broader push toward electrification, improved IAQ, and carbon-smart construction continues to intensify. Wood fiber insulation stands out as a practical, scalable step toward code compliance, healthier buildings, and industry leadership.

The building industry has an opportunity to align every phase of construction – design, sourcing, installation, and performance – with a carbon-negative, renewable insulation product – TimberHP.