TimberBatt™ Earns Third-Party Verified EPD—Proving It Stores More Carbon Than It Emits

We’re excited to share a major milestone: TimberBatt™ wood fiber insulation now has a third-party verified Environmental Product Declaration (EPD).

In simple terms, an EPD means a product’s environmental impacts have been independently measured, verified, and published using internationally recognized standards. For TimberBatt, the results confirm what we’ve believed all along: TimberBatt doesn’t just reduce carbon emissions—it actively stores carbon.

A Third-Party Verified, Carbon-Storing Insulation

Developed using One Click LCA and independently verified by EPD Hub Limited, TimberBatt’s EPD complies with ISO 14025 and ISO 21930:2017. The declaration evaluates environmental impacts across the full life-cycle scope, including:

- Cradle-to-Gate (A1–A3)

- Transport & Installation (A4–A5)

- End-of-Life (C1–C4)

- Module D (beyond building life)

The results show that TimberBatt is a net carbon-storing insulation material, with a negative global warming potential (GWP) driven by biogenic carbon stored in the wood fiber feedstock.

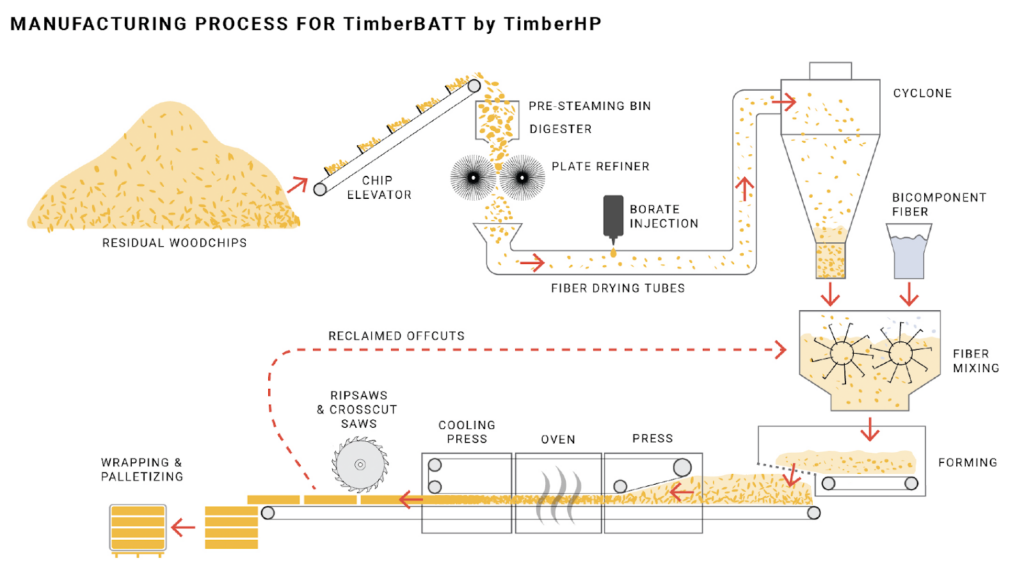

On a cradle-to-gate (A1–A3) basis, TimberBatt stores approximately 1.34 tons of CO₂ per ton produced, increasing to 1.59 tons when full life-cycle and Module D impacts are included. This carbon storage is enabled by TimberBatt’s material and manufacturing approach:

- Made from residuals of lumber manufacturing and forest management

- Manufactured using renewable electricity, including hydropower

- Carbon stored in the insulation remains locked in place for the life of the building

This fundamentally differentiates TimberBatt from conventional insulation products derived from glass or mineral wool fibers.

A New Category of Insulation: Carbon-Storing by Design

Most insulation materials carry a positive embodied carbon footprint because their production requires energy-intensive processes that generate greenhouse gas emissions. As a result, even high-performing

options like mineral wool contribute to upfront emissions before a building is ever occupied.

TimberBatt represents a new category of insulation:

- Carbon-storing, not just carbon-reducing

- High thermal and acoustic performance

- Fire-code compliant and commercially available

- Costs less than conventional mineral wool insulation

Rather than adding carbon to the atmosphere, TimberBatt stores atmospheric carbon inside the building envelope, helping to shift buildings from being a climate liability to being part of the climate solution.

What Does “Carbon-Storing Insulation” Mean in Practice?

One of the most compelling aspects of carbon-storing insulation is how simple the impact can be.

Reducing embodied carbon doesn’t always require new technologies, complex design changes, or higher costs. Sometimes, it comes down to a single specification decision.

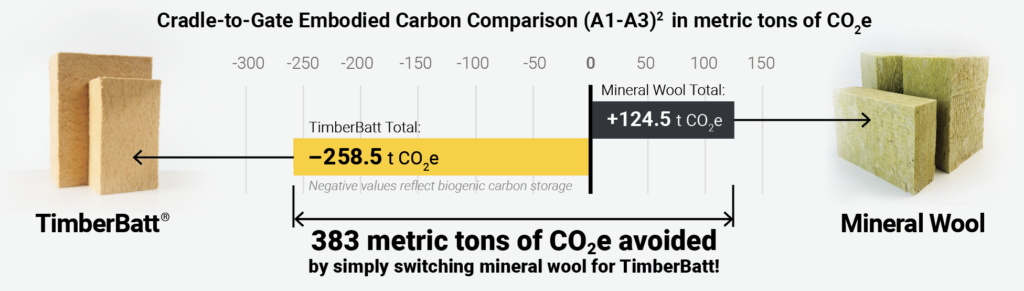

To illustrate this, TimberHP modeled a mid-rise, multifamily building where the insulation specification is changed from mineral wool batts to TimberBatt—while holding building geometry and performance constant.

Modeled project example:

- Six stories

- ~100+ dwelling units

- Greater Boston area

- Interior cavity and roof batt insulation applications, totaling 113,700 cubic feet of insulation

Using product-specific EPD data and project-specific quantities, the modeled analysis shows that switching from mineral wool to TimberBatt can avoid approximately 380+ metric tons of CO₂e in upfront embodied carbon.

That level of impact is extraordinary for a single material substitution—and it happens immediately, at the time of construction.

Translating Carbon Savings Into Real-World Terms

To make that impact easier to visualize:

- ~380 metric tons of CO₂e avoided is equivalent to

- Nearly 1 million miles of driving in a typical passenger vehicle

- Or roughly 370 one-way trips between Boston and San Francisco

And importantly, this is upfront embodied carbon—not an annual operational estimate. The climate benefit is realized as soon as the building is constructed.

Performance, Cost, and Constructability Still Matter—and TimberBatt Delivers

Crucially, these carbon reductions do not come at increased cost or compromising performance or practicality. TimberBatt:

- Meets fire-code requirements

- Delivers competitive thermal performance

- Exceeds mineral wool in acoustic absorption for cavity applications

- Installs like conventional batt insulation

- Is manufactured domestically and available at commercial scale

- Is typically lower-cost than mineral wool

For architects, builders, and developers, this represents a rare alignment: lower embodied carbon, strong performance, familiar installation, and no technical or regulatory barriers.

A Measurable Climate Action Available Today

As embodied carbon becomes a critical consideration in building design, materials that actively store carbon—rather than simply emit less—represent a meaningful shift in how we think about climate-aligned construction.

TimberBatt’s verified EPD confirms that wood fiber insulation can play a powerful role in reducing the carbon footprint of buildings, while delivering the performance the industry expects.

In an era where climate targets increasingly demand measurable, immediate reductions, switching from mineral wool to TimberBatt is one of the simplest, fastest, and most effective material substitutions available for reducing embodied carbon in construction.

Notes on Data & Modeling

The multifamily example above is a modeled comparison using product-specific EPD data and representative project quantities. Actual project results will vary based on building design, scope, and application. TimberHP continues to collaborate with project teams and LCA practitioners to evaluate real-world buildings using verified EPD data.

TimberBatt is supported by a third-party verified Environmental Product Declaration developed using OneClick LCA and verified by EPD Hub Limited in accordance with ISO 21930:2017 and ISO 14025 under EPD Hub Core PCR version 1.2 (24 March 2025). The declared unit is one square meter of insulation at RSI 1, with a declared unit mass of 1.84 kilograms. TimberBatt’s cradle-to-gate (A1–A3, TRACI) global warming potential is −2.47 kg CO2e per declared unit, reflecting the biogenic carbon stored in the wood fiber relative to manufacturing emissions; end-of-life emissions are not included in A1–A3. By comparison, ROCKWOOL Comfortbatt WS R13, reported on the same declared unit basis, carries a positive cradle-to-gate GWP of approximately +1.29 kg CO2e per declared unit.