Available Now!

TimberBoard

Rigid Exterior Continuous Insulation

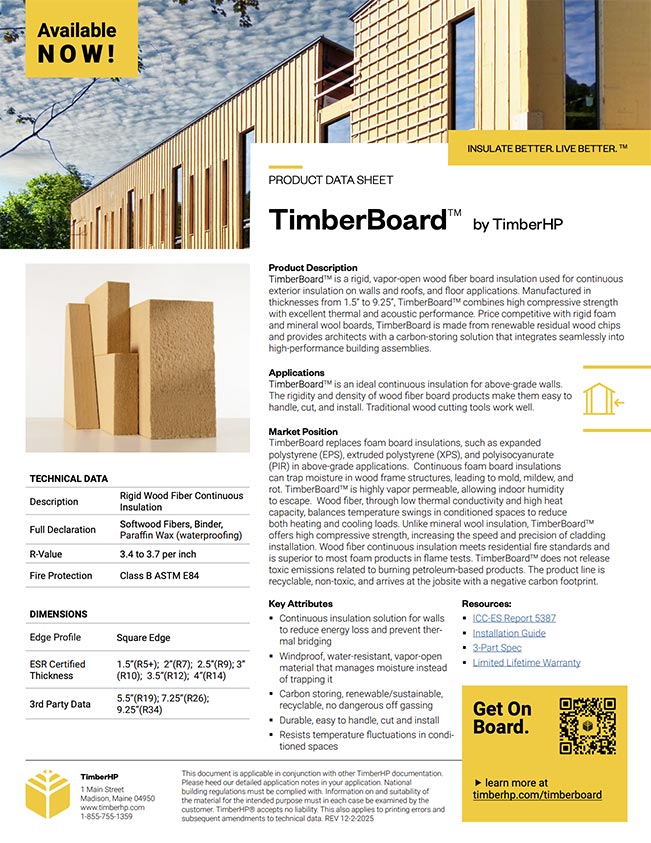

TimberBoard wood fiber insulation is a rigid continuous exterior insulation for wall, floor, and roof applications, offering superior carbon storage, moisture management and compressive strength.

TimberBoard Technical Specifications

| PROPERTY | VALUE |

|---|---|

| R-Value | R-3.4 — R-3.7 / inch |

| Thickness Available | Single ply, 1.5”(R5+); 2”(R7); 2.5”(R9); 3” (R10); 3.5”(R12); 4”(R14); 5.5”(R20); 7.25”(R26); 9.25”(R34) |

| L x W | 4’ x 8’ |

| Density | Ranging from 6.8 to 9.4 lb/ft³ |

| Vapor Permeability | 15-22 perm @ 1 inch |

| Compressive Strength | 10-20 psi |

| Fire Resistance | Meets ASTM E84 Class B Flame / Smoke |

Fire-Resistant

Meets ASTM E84 Class B ratings for flame and smoke spread performance even without the use of borate, with a Class A rated board coming soon.

High Thermal Performance

All-season thermal storage and draft reduction helps to meet Passive House, LEED, and energy stretch code targets.

Acoustic Comfort

Excellent sound absorption supports privacy and comfort in multifamily and commercial interiors.

Lowers Carbon Footprints

Wood fiber insulation naturally stores atmospheric carbon throughout its entire lifecycle, lowering the carbon footprint of the built environment.

Vapor-Open

Provides wind-tight and water-resistant performance that repels moisture without trapping humidity, reducing the potential for mold, rot, or condensation and improving indoor air quality.

Safe to Handle

Itch-free and has no VOCs, formaldehyde, or added toxins. Declare labeled and Red List Free.

We recently completed our first home, insulated with TimberHP. We have been following the development of the company for those last couple years and eagerly awaited the launch of the product. We were excited about TimberHP because it gives us a high-performance insulating package that will allow water to escape and not grow mold or rot the sheathing. An added benefit was the local aspect of the product using a lot of waste material.

Kurt Clason

Clason Remodeling Company – 2022 National Remodeler of the Year

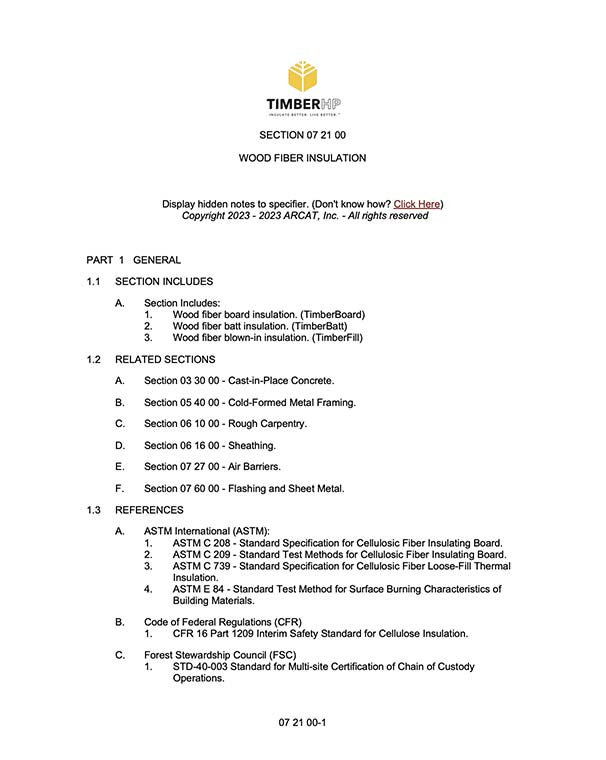

Applications

TimberBoard is suitable for a range of assemblies, whether you’re looking for heat resistance to improve the performance of an older home or want to ensure the resilience and long-term energy efficiency of new construction.

Roofs and Above-Grade Walls

TimberBoard adds robust thermal performance and moisture-resistant durability to roof and wall assemblies—enhancing building envelope strength in both residential and commercial construction.

Flooring

Used beneath flooring systems, TimberBoard helps buffer temperature swings and dampen sound, while providing added structural resilience and a smoother surface for finished floors.

Ceilings

Installed over ceiling framing, TimberBoard contributes to thermal control and acoustic comfort while supporting a continuous, breathable barrier across building levels.

Continuous Exterior Insulation

As a continuous insulation layer, TimberBoard reduces thermal bridging, boosts energy efficiency, and offers exceptional weather resistance—ideal for high-performance building envelopes.

TimberBoard FAQs

Q: Will my building department allow me to use TimberBoard?

A: Timber Board is a Building Code recognized insulation product validated in ICC-ES ESR-5387. This evaluation report outlines the scope of the Building Code recognition of TimberBoard in accordance with the 2018, 2021 and 2024 IBC and IRC. Building officials nationwide use ICC-ES evaluation reports to validatebuilding products that meet strict testing and performance standards.

Q: Will TimberBoard Burn?

A: TimberBoard has been tested for flame spread and for smoke development and carries an ASTM-E 84 Class B fire classification. When exposed to direct flame, the surface of the board chars, whereas many foam plastic insulations melt or burn away, potentially leaving voids in the wall assembly.

Q: How do I cut TimberBoard?

A: TimberBoard can be cut using wood cutting jobsite tools, with the specific approach depending on board thickness. A General-purpose wood circular saw blade with 20 to 30 teeth is recommended for clean, efficient cuts.

1.5″–2″ TimberBoard: Boards can be cut using standard circular saws (skill saws) & table saws.

2.5″–3.5″ TimberBoard: These thicknesses can still be cut using standard wood-cutting tools, such as circular saws or table saws. Dust extraction is recommended to help keep the blade clear and maintain cutting efficiency.

Q: Will TimberBoard decay or attract bugs?

A: TimberBoard resists decay and insects when stored and installed as directed. To keep pests out, bug-screen mesh should be installed continuously at both the top and bottom of rainscreen cavities. Decay and insect issues are best handled by assembly solutions not insulation solutions.

Q: Will TimberBoard trap water if it gets wet?

A: A paraffin wax additive and the binder in TimberBoard allows it to repel water. If TimberBoard does get wet, it has a unique drying capability where it quickly and evenly distributes water to the air-exposed surface of the board allowing for quick, balanced drying. Cut edges repel water as well because the wax and binder is at the fiber level.

Will my building

Q: Where should I install the Water Resistive Barrier (WRB) with Timberboard?

A: The water resistive barrier (WRB) may be installed either on the interior or exterior side of the TimberBoard. Our installation information routinely indicatesthe WRB location against the wall sheathing. This location allows for straightforward flashing at penetrations and overall WRB continuity.

WRB’s located on the outside of the TimberBoard require attention to details related to flashings and WRB continuity.

Q: Will TimberBoard reduce sound transmission through the wall?

A: Yes. TimberBoard has very impressive sound absorbing and dampening properties. Acoustic testing has shown that TimberBoard absorbs up to 85% of the sound directed at the surface. Anything over 80% is considered very effective. Please refer to our acoustic testing data for more details.

Q: Can TimberBoard be used structurally?

A: Wood fiber boards like TimberBoard are not structural bracing elements and cannot be used for racking resistance or primary structural support. The installation guide similarly treats TimberBoard as non-structural insulation layers attached to timber or masonry substrates that provide the actual structural capacity.

How Can We Help?

Contact Support

Our support team is ready to provide answers to your questions or concerns.

Contact Support