Can You Really Build Better With Wood Fiber Insulation?

What it means to “build better” is different for everyone; it can refer to reaching sustainability goals, finding more efficient ways to meet building codes, utilizing advanced building technologies, or increasing overall building durability and resilience.

However you define “building better” for your specific project, wood fiber insulation adds a whole new meaning. What have largely been singular achievements – like reducing a building’s carbon footprint or designing for greater energy efficiency – can now be collectively attained with wood fiber insulation.

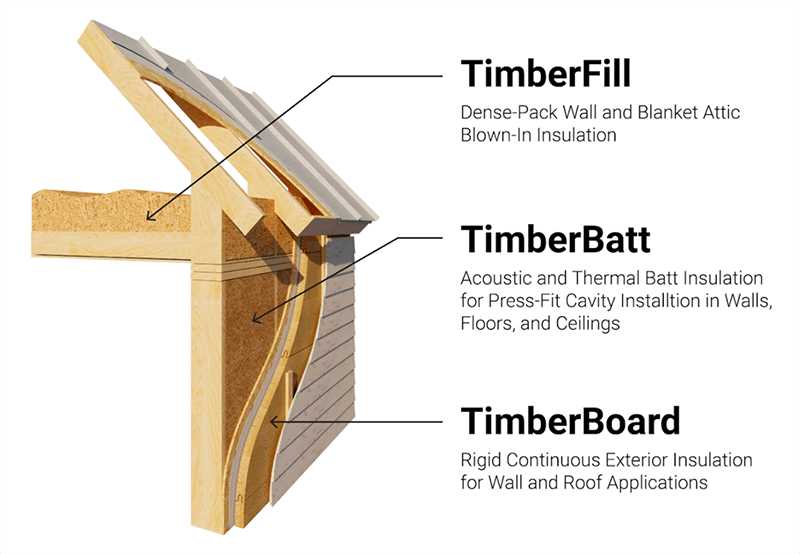

From our US-based manufacturing facility, TimberHP produces three wood fiber insulation products: TimberBatt, TimberFill, and TimberBoard, and all three support a strong performance and sustainability narrative, having been used in everything from historic retrofits to Passive House construction.

Once you understand what wood fiber insulation is, the question becomes: “How will it help me build better?”

For specifiers and installers: This article explains how wood fiber insulation is changing the way we think about construction and the standards that guide product decisions.

You’ll learn how wood fiber insulation:

- satisfies building codes while delivering certified performance backed by decades of proven use.

- solves common challenges and issues experienced with more traditional insulation solutions.

- helps you meet important project goals, whether related to sustainability or performance.

Building Trust: Codes, Compliance, & Performance

Delivering on the Core Requirements for Construction Materials

Insulation choice typically comes down to two preferences:

- Sticking with the long-used, often cheaper fiberglass and spray foam options that can get the job done sufficiently to meet code requirements and deliver on basic performance expectations.

- A desire to adopt more sustainable materials and find something healthy and renewable that’s easy to work with and won’t impact performance.

Wood fiber insulation satisfies the latter – and then some. Building better with wood fiber insulation is possible on multiple fronts because it’s a material that’s healthier, lowers carbon footprints, and delivers thermal and acoustic performance – naturally. We know how to build efficiently with the renewal resource of lumber; therefore, wood fiber insulation, the byproduct of lumber production, is a no brainer.

But beyond the physical (no itch!) and emotional (made in Maine) feel-good stories, wood fiber insulation also checks the boxes for the technical stuff too – meeting building codes and carrying the right certifications for compliance and performance requirements.

Codes & Certifications

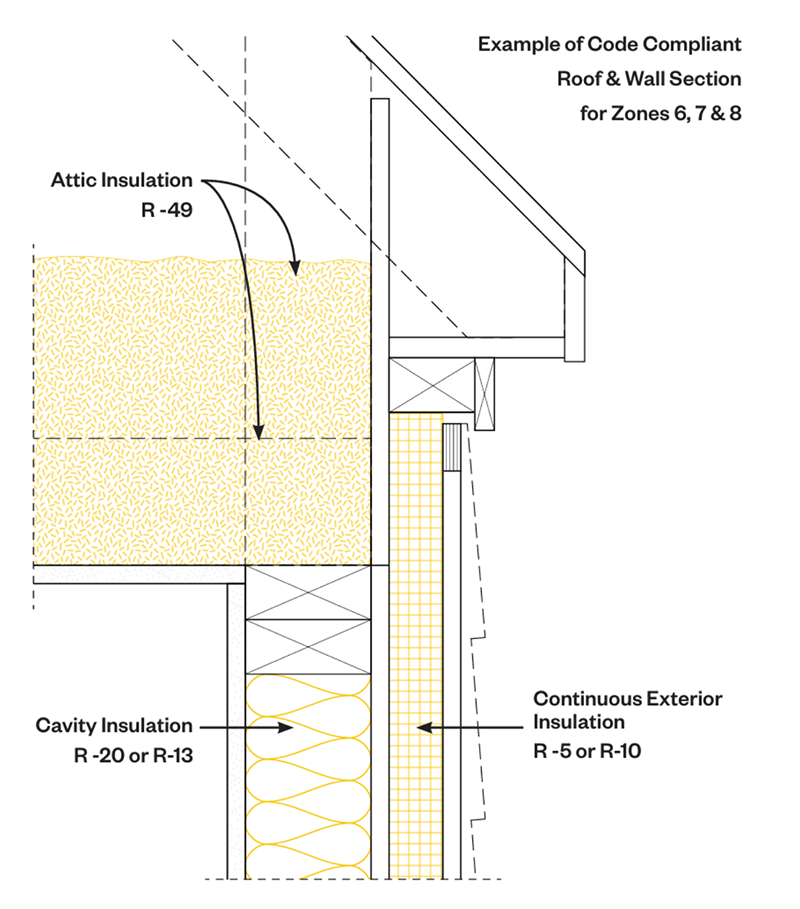

Building Code Compliance: Our wood fiber insulation products are designed to meet International Building Code (IBC) and International Residential Code (IRC) standards, making TimberBatt, TimberFill, and TimberBoard a great fit for residential, multi-family, and commercial construction.

Fire Resistance: TimberBatt and TimberFill achieve an ASTM E84 Class A flame and smoke spread rating, while TimberBoard achieves Class B without any added fire retardants. TimberBatt and TimberFill are treated with liquified borate, which saturates the wood fiber and provides a superior long-term solution for fire, bug, and moisture/mold resistance. Independent certification through ICC-ES further validates fire-resistance claims and safe installation guidelines.

| TimberBatt | ASTM E84 Class A <25 Flame and <450 Smoke spread | FSI: 10 SDI: 15 | – Superior fire resistance – Burns very slowly – Produces minimal smoke |

| TimberFill | ASTM E84 Class A <25 Flame and <450 Smoke spread | FSI: 5 SDI: 0 | – Superior fire resistance – Minimal contribution to fire spread – Highest rating under ASTM E84 |

| TimberBoard | ASTM E84 Class B Flame and Smoke Spread | FSI: 26-75 SDI: 450 or less | – Burns at a moderate rate – Moderate smoke production – No added fire retardants |

Performance

Thermal Performance: TimberBatt delivers about R-4 per inch, and TimberBoard ranges between R-3.4 to R-3.7/inch, with excellent thermal mass for year-round comfort

TimberBatt

Acoustic & Thermal Cavity Insulation

R-3.7 to R-4 per inch

TimberFill

Dense Pack & Blanket Insulation

~R-3.8 per inch

TimberBoard

Exterior Continuous Insulation

R-3.4 to R-3.7 per inch

Acoustic Performance: Fire-rated assemblies incorporating TimberHP deliver Sound Transmission Class (STC) ratings of 50–55, and Outdoor-Indoor Transmission Class (OITC) ratings predominantly above 30. TimberBatt alone boasts an exceptional Noise Reduction Coefficient (NRC) of 1.15, far exceeding the desired minimum of 0.80.

| Assembly | STC* | OITC | RAL# |

|---|---|---|---|

| 3-5/8″ Metal Studs 16″ o.c. TimberBatt acoustic, RCSD on Source Side, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 53 | 34 | TL23-007 |

| 3-5/8″ Metal Studs 16″ o.c. TimberBatt acoustic, Single Layer of 5/8″ Type X Gypsum Board on Both Sides | 46 | 30 | TL23-008 |

| 3-5/8″ Metal Studs 24″ o.c. TimberBatt acoustic, RCSD on Source Side, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 53 | 32 | TL23-009 |

| 3-5/8″ Metal Studs 24″ o.c. TimberBatt acoustic, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 49 | 30 | TL23-010 |

| 2×4 Wood Studs 16″ o.c., TimberBatt, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 37 | 27 | TL23-011 |

| 2×4 Wood Studs 16″ o.c. TimberBatt, RCSD on Source Side, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 50 | 31 | TL23-012 |

| 2×4 Wood Studs 16″ o.c. TimberFill, RCSD on Source Side, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 50 | 32 | TL23-013 |

| 2×4 Wood Studs 16″ o.c. TimberFill, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 32 | 27 | TL23-014 |

| 2×6 Wood Studs 16″ o.c. TimberBatt, RCSD on Source Side, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 55 | 37 | TL23-015 |

| 2×6 Wood Studs 16″ o.c. TimberBatt, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 36 | 28 | TL23-016 |

| 2×6 Wood Studs 16″ o.c. TimberFill, RCSD on source side, Single Layer Of 5/8″ Type X Gypsum Board on Both Sides | 53 | 38 | TL23-017 |

| 2×6 Wood Studs 16″ o.c. TimberFill, Single Layer Of 5/8″ Type X Gypsum Board on Both Side | 38 | 28 | TL23-018 |

Material Details

| Product Name | Thickness | NRC** | RAL # |

|---|---|---|---|

| TimberFill | 5-1/2 inch | 1.15 | A22-003 |

| TimberBatt | 5-1/2 inch | 1.15 | A22-007 |

| TimberBoard (single layer) | 1-1/2 inch | 0.85 | A22-004 |

| TimberBoard (two layers) | 3 inch | 0.85 | A22-005 |

| TimberBoard (single layer) | 5-1/2 inch | 1 | A22-006 |

Moisture Management: Wood fiber insulation products are vapor-open and effectively manage moisture and condensation, helping prevent mold and rot, and promoting improved air quality in the built environment.

At a basic level, wood fiber insulation delivers on the core requirements for light frame construction in residential and commercial building codes and compliance standards.

TimberHP brought these products to the U.S. market, but wood fiber insulation has been widely used in Europe for more than two decades, earning a respected reputation based on the same certifications and proven performance.

While it is a “new” product in America, its quality and performance quality is long-known in European markets. Now, architects, builders, and installers alike can enjoy the same value in the U.S. with no concern for how it fits with this country’s building and construction requirements.

Ease of the Install: Efficiency, Handling, and Fit

Addressing the Challenges of Traditional Insulation Materials

Traditional insulation materials like fiberglass and spray foam have been long-used, but as building professionals begin looking for healthier and more sustainable solutions, these products are also increasingly falling out of favor.

Even where sustainability isn’t playing as large of a role in decision-making, overall health and wellness is. Healthy homes no longer have to be curated from the inside – they begin with construction.

And the benefits of wood fiber insulation really do start at construction.

Wood fiber insulation is making it easier than ever for building professionals to install a healthy, sustainable, high-performing insulation that solves many current insulation challenges and, importantly, is itch-free and doesn’t require PPE.

Budget, Availability & Compatibility

TimberHP batts and loose-fill products arrive ready for site installation with a modular design that ensures compatibility with standard wall and ceiling cavities.

TimberBoard, which is being rolled out in rigid board form in late 2025, complements these offerings, providing a continuous exterior insulation solution not currently available in America.

Ease of Handling & Installation

TimberBatt is designed for friction-fit installation, cuts cleanly, and doesn’t itch or produce debris.

TimberFill is a safe-to-handle, debris-free dense pack blown in and attic blanket insulation. Where installers have to wear PPE to handle fiberglass and spray foam, TimberFill doesn’t require special protective gear and won’t irritate the skin or cause itchiness.

TimberBoard installs with standard carpentry tools—no re-tooling required—and when you cut it, you get sawdust (no microplastics blowing away in the wind!)

Sustainability Benefits Without Compromise

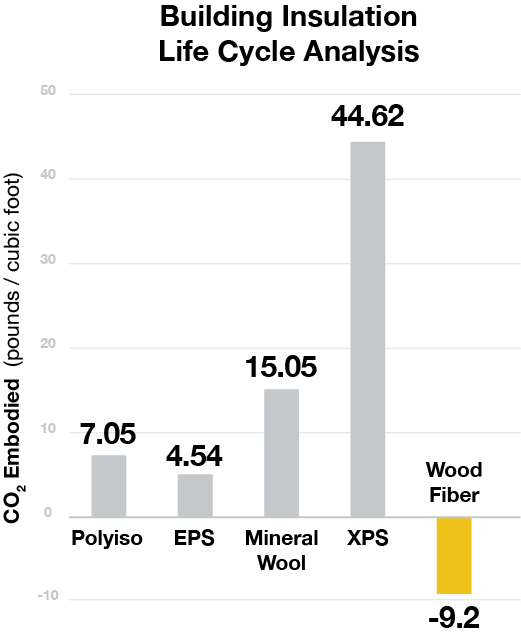

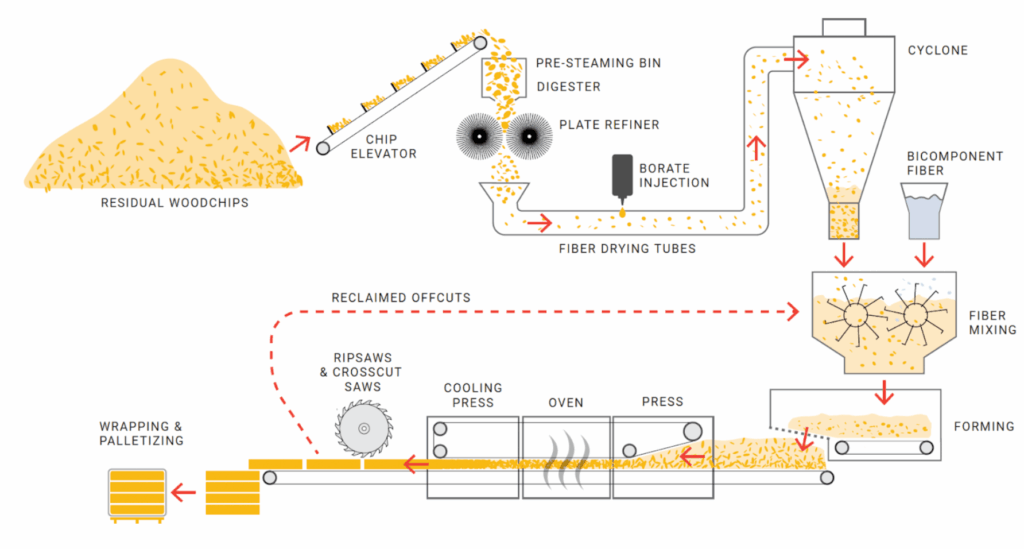

Made from residual softwood chips and manufactured in America, TimberHP products store carbon in the built environment, ultimately lowering a building’s upfront carbon footprint. It’s free from harsh fibers or off-gassing, and contributes to building longevity. A building insulation life cycle analysis shows that wood fiber drastically reduces carbon emissions compared to other materials in the manufacturing process. We recycle off cuts and out of spec material back into the process minimizing manufacturing waste.

Wood fiber insulation contributes to energy-efficient construction by delivering reduced thermal bridging, best in class resistance to short term heat gains even compared to higher R value insulations, and quiet, comfortable interiors without complicating installation or extending timelines.

Validating Real-World Performance

Because Results Speak Louder Than a Promise

Hold wood fiber insulation up against any other insulation product from spray foam to mineral wool and you’ll see some similarities (like high R values) and some differences (wood fiber is the most scalable bio based, renewable insulation on the market).

Let’s take a closer look at the manufacturing process for TimberBatt to see more clearly how we provide a high-performance insulation material with a fully renewable lifecycle.

How is it renewable? At the end of its service life, TimberBatt and TimberBoard can be removed with standard tools and handled like other wood-based building materials. Because it’s made almost entirely from wood fiber, it carries the inherent potential for recycling, reuse, or energy recovery—pathways that align with the industry’s move toward circularity. While large-scale recycling systems for wood fiber insulation are still emerging in North America, TimberHP insulation is designed with that future in mind. Choosing TimberHP means specifying a product that not only performs today but is positioned to contribute to more sustainable building practices tomorrow.

Check enough boxes and it starts to become clear that wood fiber has a distinct leg up. But the real proof, as with anything, is in real-world use. and we’ve done enough testing to accurately validate just how superior TimberHP wood fiber insulation is to other products when it comes to overall performance in the built environment.

An “I Can’t Hear Anything” Level of Acoustic Performance

TimberHP’s acoustic testing data underscores its ability to create quieter, more comfortable spaces. Assemblies using TimberBatt or TimberFill deliver STC 50–55 and NRC ratings well above 0.80, ideal for multi-unit dwellings, schools, and commercial buildings.

See more about sound: Rated Acoustic Assemblies

Standard-Setting Fire Resistance

All TimberHP wood fiber insulation products earn top fire-performance marks (ASTM E84 Class A/B with 1- and 2-hour fire ratings) and enhance fire-resistance in assemblies; wood-stud walls see rated increases thanks to these materials. While our products are treated with borate, it is applied in a liquid form, allowing it to saturate into the wood fiber, unlike cellulose which uses a powder coating of borate. Saturation provides a superior, longer-term performance against fire, moisture, and pets.

Easy Breathing

All TimberHP wood fiber insulation products are vapor open, meaning they provide wind-tight and water-resistant performance that repels moisture without trapping humidity, reducing the potential for mold, rot, or condensation.

Everyone can breathe easier knowing the air is freer from potential allergens or irritants than in homes that use standard insulation – additionally, using wood fiber insulation removes the chance of chemicals leaching into the air from fiberglass and spray foam materials.

Comfortable Through All Seasons

TimberBatt, TimberFill, and TimberBoard all offer R values at or above the standard for residential or commercial building performance, and coupled with our insulation’s vapor-open and renewable material makeup, you can infuse your project with exceptional thermal storage, draft reduction, and temperature stabilization. Wood fiber insulation provides a superior thermal barrier for year-round comfort.

CASE STUDY

Insulating Multifamily Housing

Since 2023, Avesta has specified TimberHP products in 5 multi-building projects across Maine. In multifamily housing, acoustic comfort is critical, and wood fiber insulation delivers on that need while also providing high performance and sustainability.

Project Highlights

Maine Locations: Gray, Lewiston, Farmington, and Westbrook

Build Type: Multifamily housing units

Specs: 2 – 3-story wood frame construction

Sizes: 21,000 to 60,000 square feet

TimberHP Products: TimberFill for exterior walls, and TimberBatt for interior walls

Why TimberHP Was the Right Fit

TimberHP products allowed Avesta Housing and project partners to meet important goals for each multifamily housing unit:

TimberFill:

- High R value exterior wall insulation

- Effective sound dampening—especially important for multifamily builds

- No use of spray foams or insulations with harmful chemicals

- Cost effective with easy installation and high performance

- Easy to visually inspect to verify density and coverage, ensuring long-term performance

TimberBatt:

- High R value interior wall insulation

- Effective sound dampening—especially important for apartments near mechanical components like elevators

- Cost effective with easy installation and high performance

Integrating Wood Fiber Insulation Into Your Next Project

The Total Package for Specifiers and Installers

Adopting wood fiber insulation for your next project is just smart. It’s cost-competitive with mineral wool but is made from renewable materials. It is sourced and manufactured in the U.S. from our plant in Madison, Maine, but has its origins in Europe as a trusted insulation material.

Now, let’s break down how wood fiber insulation can help you succeed and elevate your next project:

- Easy to spec our code-compliant, triple-rated (thermal, acoustic, fire) solutions.

- Meet sustainability goals with renewable, non-toxic insulation that supports certifications and health.

- Achieve design ambitions while also attaining durable insulation performance

- Products ready to fit into standard assemblies—no custom adjustments.

- Quieter, safer, and cleaner handling conditions than traditional insulation.

- Reliable, long-term performance that aids energy efficiency and occupant satisfaction—without adding complexity.

If you’re contemplating which type of insulation material to use for your next project, let us make the decision easier. Wood fiber insulation is quickly becoming a go-to in the building and construction industry, and from price to performance, it delivers.

See how TimberHP helped Avesta Housing solve common challenges in multifamily living spaces and create quiet, healthy, high-performing housing.

Add TimberHP to Your Project